BEARINGS.

When purchasing a new reel or second hand not knowing the history behind the reel its best to service easily accessed bearings mostly on the left side plate asap. I have not come across a reel I owned that saw bearing trouble even when bearings was not serviced before extended use and then a service. More of a do as I say don’t do as I do type of statement ☺.

If the right side plate is a part you don’t want to remove at first if nothing feels wrong or no audible noise that might mean something wrong in r/s plate then it can be left till when a major service can be done.

Where reel bearings go the better the quality the better longevity you get out of its use. Fishing salt water if fly, boat or rock and surf for a bearing the bare minimum is stainless steel (s/s). Mild steel really does not stand up to this application as will be shown later.

Reel bearings can be separated in 4 types.

1. Full ceramic bearing.

2. Hybrid bearing.

3. Stainless steel bearing.

4. Mild steel bearing.

1. FULL CERAMIC BEARINGS.

Full ceramic bearings is in a league of its own. Not ceramic like a CHINA set lol these bearings have a glass like feel to it. This glass like finish reduces friction much more tha as/s bearing offering a much higher rpm during a cast. A normal non abec rated s/s bearing can be bought for as little as R30 where a full ceramic bearing you can expect to pay as little as R800 for one bearing.

Of the cheapest ive seen is $47 (excl p&p) and most expensive yet seen is $560 (both US$ excl. p&p) per bearing. It could be found cheaper but questions might arise to its quality or usage, skateboard bearings come to mind and not suitable for fishing application. Popular reel size bearings might also be an issue.

Biggest advantages it has over other bearings is its lighter, has a much higher rpm and in this case a reel can drastically improve distance during a cast as well as a far higher tolerance for salt water and can even withstand acid, can withstand heat up to 1880 fahrenheit, non conductive so not attracting magetic field, requires less maintenance because of material used as opposed to s/s to ward off rust etc.

2. HYBRID BEARINGS.

Not full ceramic and more a ceramic hybrid (CH) with steel and ceramics in makeup process. Outer and inner race is made of steel but ball’s is made of ceramic. Lighter than plain steel increasing speed theses ceramic balls is much less prone to corrode like stainless balls. ABEC 7 Orange seal bearings is one popular example. The rubber seal used in this bearing also is non contact with either race increasing speed.

3. STAINLESS STEEL

There’s stainless and chrome. Of the two the stainless is better. Chrome has less chromium (1,5%) making it more prone to rust whereas stainless has a higher chromium (18%) content for better rust resistance.

4. MILD STEEL

Last choice for salt water applications. Should be used as a backup only when better quality material used for a bearing can be purchased. Not much to praise here ☺.

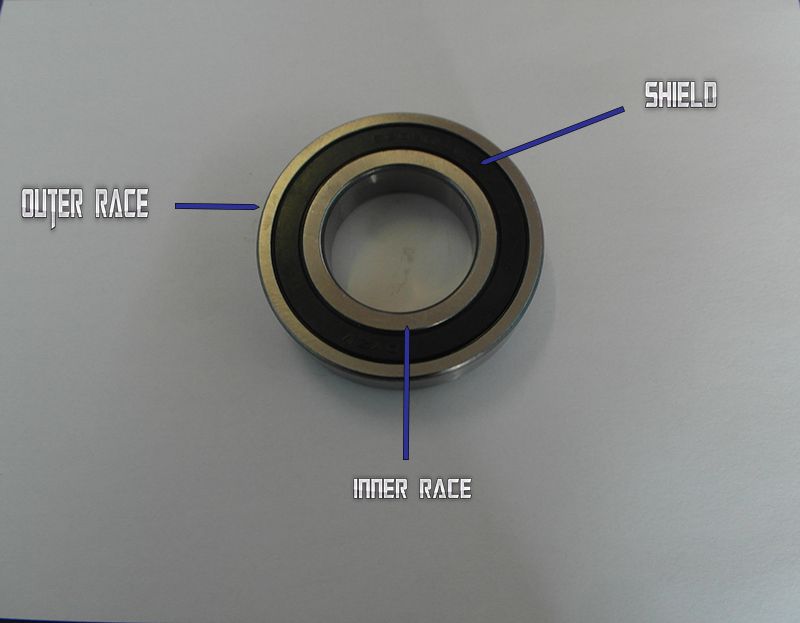

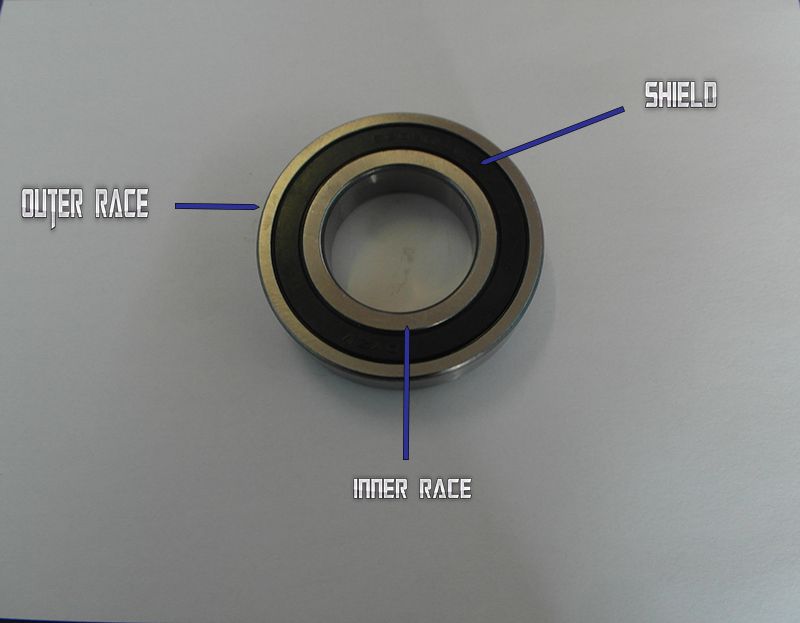

THE MAKEUP OF A BEARING

Bearings are made up of 4 parts. The outer race that sits flush against the reel, the inner race that is the moveable part of the bearing that’s also where the spool shaft fits in making the complete part moveable, stainless or rubber shields and a cage that keeps the balls of the bearing together.

INNER RACE

The part that spins freely, allowing bearing its speed and ultimately the reel its achievable distance depending on amount of contact made between inner race and spool shaft/spindle. This part of the bearing can be polished to remove any burrs and offer smoother rotation of the spool. Care must be taken and not use too abrasive materials to polish this part. Cotton swabs is a good start.

BEARING SHIELDS

To remove or not to remove. That is the question? As some shields do make contact with either the inner or outer race this does slow a bearing and spool down during a cast. Bearings where shields are left on can expect foreign contaminants like salt water or sand/dust etc to be kept in place by the shield even with maintenance. With the shield removed these foreign contaminants have a better chance of not allowed to stay put inside bearing.

Bearing shields should be removed firstly for a free spinning bearing as well as one that can be easier inspected for any signs of rust etc before it can take hold.

If you going to remove the bearing be sure you don’t want to put it back at a later stage. Some bearings do allow you to remove the clip/c-clip without damage to the shield and for that best a sharp pointed object used to first remove the c-clip then the shield carefully without it bent out of shape and now rendered useless. These shields are hard through manufacture process and once out of shape almost impossible to shape it to fit the bearing again.

When shield is removed the speed of the bearing can simply be achieved by placing it in something like a pencil or screwdriver and giving it a spin to see if it spins longer than when shield was on.

A quick look at one example of codes used for some bearings. Codes may vary from different manufacturers and different usage becoming confusing somewhat. There is a lot of information and products out there.

1. ZZS. Removable non contact shield. No contact with inner race so no compromise with bearing speed. Easy to relube. ZZS is a Double shield and ZS is a single shield..

2. ZZ. Non removable shield when installed and non contact with outer race comparable to open bearing. Single shield. ZZ for Double shield and Z for Single shield.

3. 2RS. Rubber seal that can be removed but with care. Makes contact with inner race offering better protection against foreign unwanted material but also compromises on speed with contact. 2RS for a Double shield and RS for a single shield.

4. 2RU. A non contact rubber shield that can be removed. Offers better protection than first two and without compromising speed like the 2RS. 2RU for a double shield and RU for a Single shield.

BEARING CAGES.

Main purpose is to keep the balls together. Cages do make contact with the outer and/or inner race.

EFFECTS OF SALT WATER ON BEARINGS.

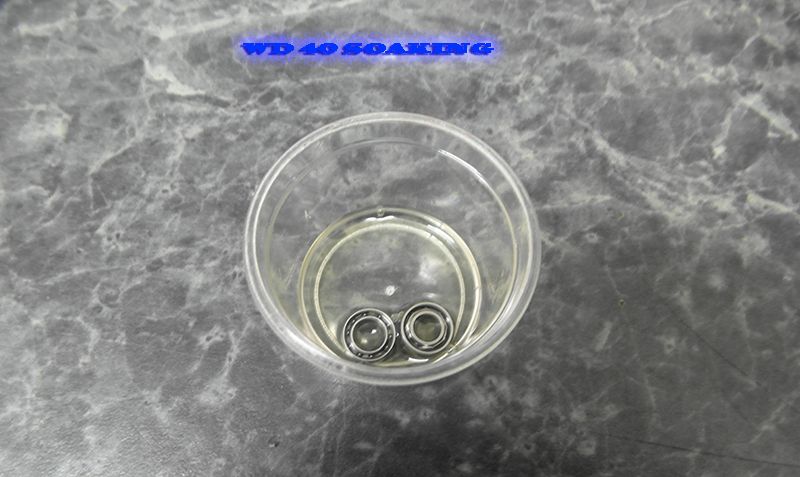

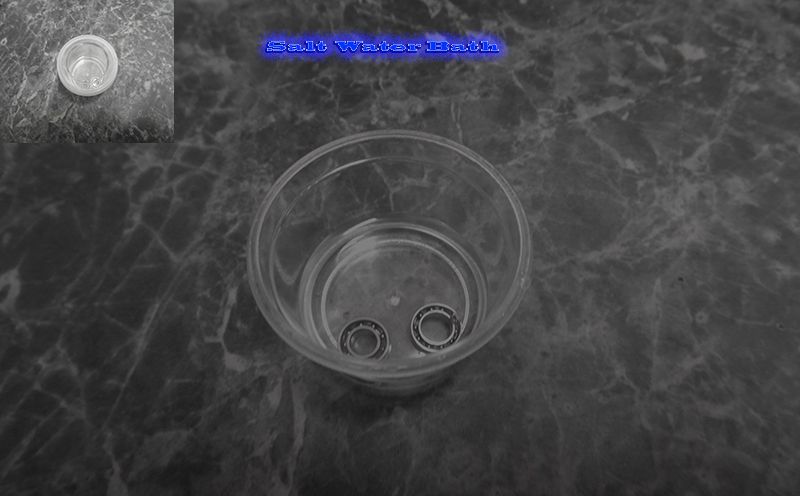

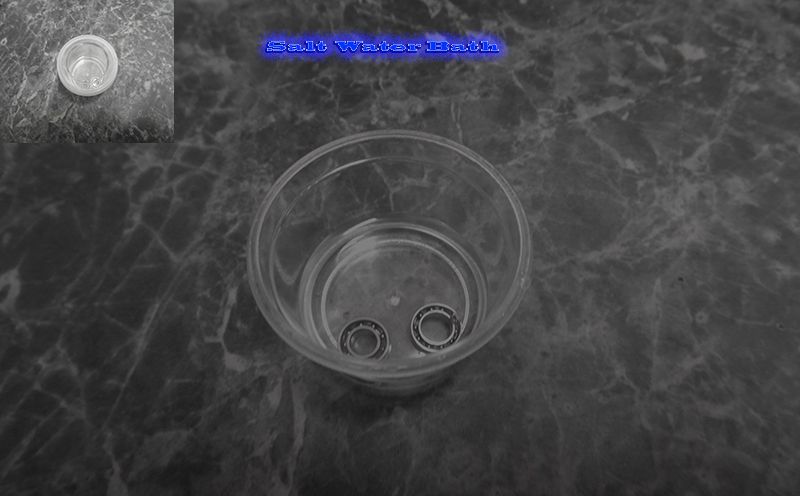

2 types of bearings I used for this home test. One a s/s non abec rated bearing and the other a mild steel. The s/s was lubed with regular over the counter oil pictured in part 1 and the mild with what I think to be better quality oil using magnatec oil.

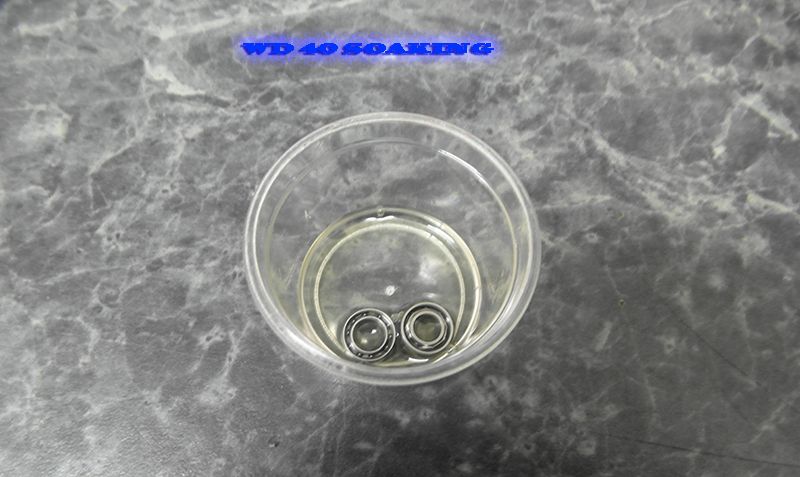

Bearings were first cleaned using WD40 then each soaked in the different oils. Each bearing with one oil only applied and not two oils per bearing.

I used sea water for this curious home test btw.

After one day there was no visible rust on both bearings.

After one week the rust can be seen floating on top of the surface.

The s/s bearing had rust but mostly surface with some of it wiped away leaving less actual rust on bearing. The mild steel with what I feel is a better oil looking somewhat expectedly worse. Was hoping for more but yet with quality oil was not sufficient for the mild steel bearing.

After 3 weeks rust was more widespread and bearings looking much the worse.

For the heck of it ☺ I placed both bearings as was taken out of salt water without extra lubrication into some Coke. I had seen the effects Coke has on a lollipop for a short overnight experiment done for school experiment so curious to see effect on reel bearing.

After one week the mild steel was a complete different colour and completely kaput.

Not sure how much can be taken from a home test like this as at no stage during this home test was any of the 2 bearings exposed to air. With water having very little oxygen to speed up the rust process it must be exposed to air so the liquid probably protecting the bearing from rusting over a much quicker period. Might explain also why some reels recovered whilst under water with quality bearings showed not much sign of rust on the bearings with no or very little air exposure.

ABEC AND SIMILAR RATED BEARINGS.

If precision standard bearings is what you want there 3 standards to look for in a bearing when purchasing.

1. Annular Bearing Committee/Council (ABEC)

2. International Standards Organization (ISO)

3. National Standards Organization (DIN)

Below a table showing different ratings in same class if compared. Bearings might not show ABEC but perhaps ISO or DIN and with this table you can gauge quality.

ABEC 1 – NORMAL ISO – P0 / DIN

ABEC 3 – CLASS 6 / ISO – P6 DIN

ABEC 5 – CLASS 5 / ISO – P5 / DIN

ABEC 7 – CLASS 4 / ISO – P4 / DIN

ABEC 9 – CLASS 2 / ISO – P2 / DIN.

ABEC 9 not originally designed for civilian but for NASA and U.S Dept. of Defence. Now more readily available in common fishing reel bearing sizes.

https://www.youtube.com/watch?v=jfEzHreHh5I

When purchasing a new reel or second hand not knowing the history behind the reel its best to service easily accessed bearings mostly on the left side plate asap. I have not come across a reel I owned that saw bearing trouble even when bearings was not serviced before extended use and then a service. More of a do as I say don’t do as I do type of statement ☺.

If the right side plate is a part you don’t want to remove at first if nothing feels wrong or no audible noise that might mean something wrong in r/s plate then it can be left till when a major service can be done.

Where reel bearings go the better the quality the better longevity you get out of its use. Fishing salt water if fly, boat or rock and surf for a bearing the bare minimum is stainless steel (s/s). Mild steel really does not stand up to this application as will be shown later.

Reel bearings can be separated in 4 types.

1. Full ceramic bearing.

2. Hybrid bearing.

3. Stainless steel bearing.

4. Mild steel bearing.

1. FULL CERAMIC BEARINGS.

Full ceramic bearings is in a league of its own. Not ceramic like a CHINA set lol these bearings have a glass like feel to it. This glass like finish reduces friction much more tha as/s bearing offering a much higher rpm during a cast. A normal non abec rated s/s bearing can be bought for as little as R30 where a full ceramic bearing you can expect to pay as little as R800 for one bearing.

Of the cheapest ive seen is $47 (excl p&p) and most expensive yet seen is $560 (both US$ excl. p&p) per bearing. It could be found cheaper but questions might arise to its quality or usage, skateboard bearings come to mind and not suitable for fishing application. Popular reel size bearings might also be an issue.

Biggest advantages it has over other bearings is its lighter, has a much higher rpm and in this case a reel can drastically improve distance during a cast as well as a far higher tolerance for salt water and can even withstand acid, can withstand heat up to 1880 fahrenheit, non conductive so not attracting magetic field, requires less maintenance because of material used as opposed to s/s to ward off rust etc.

2. HYBRID BEARINGS.

Not full ceramic and more a ceramic hybrid (CH) with steel and ceramics in makeup process. Outer and inner race is made of steel but ball’s is made of ceramic. Lighter than plain steel increasing speed theses ceramic balls is much less prone to corrode like stainless balls. ABEC 7 Orange seal bearings is one popular example. The rubber seal used in this bearing also is non contact with either race increasing speed.

3. STAINLESS STEEL

There’s stainless and chrome. Of the two the stainless is better. Chrome has less chromium (1,5%) making it more prone to rust whereas stainless has a higher chromium (18%) content for better rust resistance.

4. MILD STEEL

Last choice for salt water applications. Should be used as a backup only when better quality material used for a bearing can be purchased. Not much to praise here ☺.

THE MAKEUP OF A BEARING

Bearings are made up of 4 parts. The outer race that sits flush against the reel, the inner race that is the moveable part of the bearing that’s also where the spool shaft fits in making the complete part moveable, stainless or rubber shields and a cage that keeps the balls of the bearing together.

INNER RACE

The part that spins freely, allowing bearing its speed and ultimately the reel its achievable distance depending on amount of contact made between inner race and spool shaft/spindle. This part of the bearing can be polished to remove any burrs and offer smoother rotation of the spool. Care must be taken and not use too abrasive materials to polish this part. Cotton swabs is a good start.

BEARING SHIELDS

To remove or not to remove. That is the question? As some shields do make contact with either the inner or outer race this does slow a bearing and spool down during a cast. Bearings where shields are left on can expect foreign contaminants like salt water or sand/dust etc to be kept in place by the shield even with maintenance. With the shield removed these foreign contaminants have a better chance of not allowed to stay put inside bearing.

Bearing shields should be removed firstly for a free spinning bearing as well as one that can be easier inspected for any signs of rust etc before it can take hold.

If you going to remove the bearing be sure you don’t want to put it back at a later stage. Some bearings do allow you to remove the clip/c-clip without damage to the shield and for that best a sharp pointed object used to first remove the c-clip then the shield carefully without it bent out of shape and now rendered useless. These shields are hard through manufacture process and once out of shape almost impossible to shape it to fit the bearing again.

When shield is removed the speed of the bearing can simply be achieved by placing it in something like a pencil or screwdriver and giving it a spin to see if it spins longer than when shield was on.

A quick look at one example of codes used for some bearings. Codes may vary from different manufacturers and different usage becoming confusing somewhat. There is a lot of information and products out there.

1. ZZS. Removable non contact shield. No contact with inner race so no compromise with bearing speed. Easy to relube. ZZS is a Double shield and ZS is a single shield..

2. ZZ. Non removable shield when installed and non contact with outer race comparable to open bearing. Single shield. ZZ for Double shield and Z for Single shield.

3. 2RS. Rubber seal that can be removed but with care. Makes contact with inner race offering better protection against foreign unwanted material but also compromises on speed with contact. 2RS for a Double shield and RS for a single shield.

4. 2RU. A non contact rubber shield that can be removed. Offers better protection than first two and without compromising speed like the 2RS. 2RU for a double shield and RU for a Single shield.

BEARING CAGES.

Main purpose is to keep the balls together. Cages do make contact with the outer and/or inner race.

EFFECTS OF SALT WATER ON BEARINGS.

2 types of bearings I used for this home test. One a s/s non abec rated bearing and the other a mild steel. The s/s was lubed with regular over the counter oil pictured in part 1 and the mild with what I think to be better quality oil using magnatec oil.

Bearings were first cleaned using WD40 then each soaked in the different oils. Each bearing with one oil only applied and not two oils per bearing.

I used sea water for this curious home test btw.

After one day there was no visible rust on both bearings.

After one week the rust can be seen floating on top of the surface.

The s/s bearing had rust but mostly surface with some of it wiped away leaving less actual rust on bearing. The mild steel with what I feel is a better oil looking somewhat expectedly worse. Was hoping for more but yet with quality oil was not sufficient for the mild steel bearing.

After 3 weeks rust was more widespread and bearings looking much the worse.

For the heck of it ☺ I placed both bearings as was taken out of salt water without extra lubrication into some Coke. I had seen the effects Coke has on a lollipop for a short overnight experiment done for school experiment so curious to see effect on reel bearing.

After one week the mild steel was a complete different colour and completely kaput.

Not sure how much can be taken from a home test like this as at no stage during this home test was any of the 2 bearings exposed to air. With water having very little oxygen to speed up the rust process it must be exposed to air so the liquid probably protecting the bearing from rusting over a much quicker period. Might explain also why some reels recovered whilst under water with quality bearings showed not much sign of rust on the bearings with no or very little air exposure.

ABEC AND SIMILAR RATED BEARINGS.

If precision standard bearings is what you want there 3 standards to look for in a bearing when purchasing.

1. Annular Bearing Committee/Council (ABEC)

2. International Standards Organization (ISO)

3. National Standards Organization (DIN)

Below a table showing different ratings in same class if compared. Bearings might not show ABEC but perhaps ISO or DIN and with this table you can gauge quality.

ABEC 1 – NORMAL ISO – P0 / DIN

ABEC 3 – CLASS 6 / ISO – P6 DIN

ABEC 5 – CLASS 5 / ISO – P5 / DIN

ABEC 7 – CLASS 4 / ISO – P4 / DIN

ABEC 9 – CLASS 2 / ISO – P2 / DIN.

ABEC 9 not originally designed for civilian but for NASA and U.S Dept. of Defence. Now more readily available in common fishing reel bearing sizes.

https://www.youtube.com/watch?v=jfEzHreHh5I